Skatepark production and materials

Materials and certificates

Tiptiptap skateparks are of high quality, durable and come with many different combination options. We offer both individual elements and large parks as a ready-made solution.

As we design and produce the skateparks ourselves, we can be flexible to take the following into account: the wishes of our users, the size of the park, the materials of the surface. Our skateparks are suitable for skateboarders and skaters as well as for BMX and scooter riders.

The materials used are weatherproof. This ensures the long service life of skateparks in different weather conditions. Only Torx screws are used for connecting the parts, making the connections strong and durable. As the riding surfaces are covered with two layers of plywood, only the top layer can be replaced if it gets worn out.

All our skatepark elements are manufactured in accordance with the safety standard EVS-EN 14974: 2019 and come with the corresponding TÜV certificate.

Our skateparks can be ordered in four different material versions: BASE, BASE +, STEEL and STEEL PRO.

Version BASE

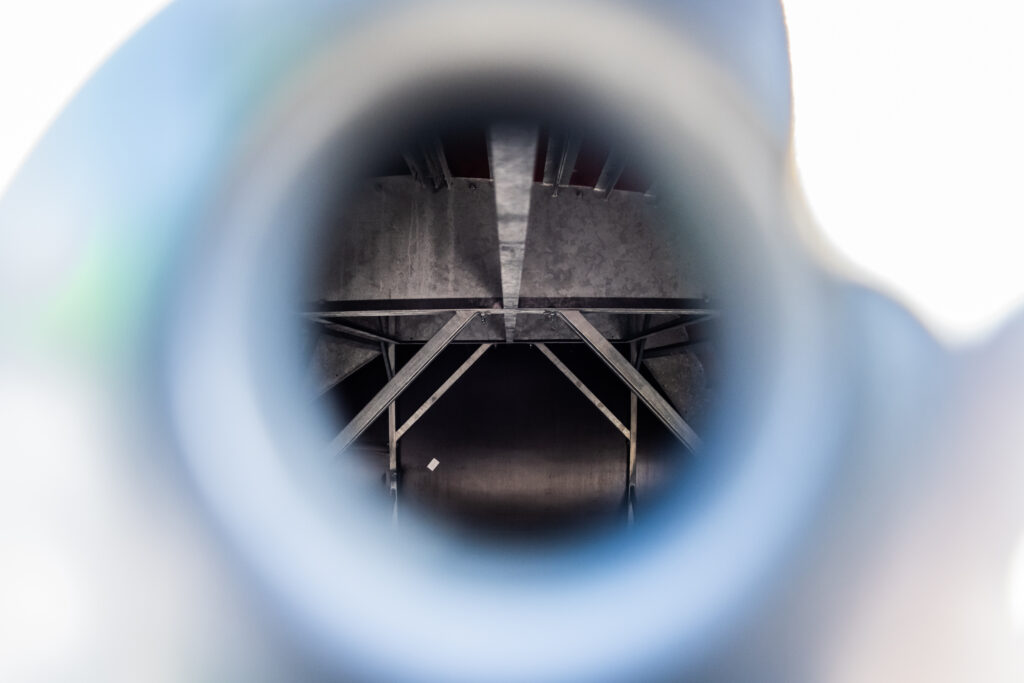

The riding surface is 9 mm FW with excellent adhesion that is extremely wear-resistant (min. 440 g / m2) and textured, and its bottom layer is made of 9-15 mm FF waterproof plywood with a phenolic coating.

The frame is 15 mm FF, the sides and back are 9 mm FF – phenol-coated laminated waterproof plywood. Vertical railings, connecting pipes and asphalt or concrete mounting plates are made of hot-dip galvanized steel. The 45 x 95 mm wooden beams of the inner frame are dried, planed and deeply impregnated.

Version BASE +

The riding surface is an extremely durable, maintenance-free and weather-resistant 6 mm composite material with a bottom layer made of 9-15 mm FF waterproof plywood with a phenolic coating.

The frame is 15 mm FF, the sides and back are 9 mm FF, made of laminated waterproof plywood with a phenolic coating. Vertical railings, connecting pipes and asphalt or concrete mounting plates are made of hot-dip galvanized steel. The 45 x 95 mm wooden beams of the inner frame are dried, planed and deeply impregnated.

Version STEEL

The riding surface is 6.5 mm FW with excellent adhesion that is extremely wear-resistant (min. 440 g / m2) and has a textured surface, and its bottom layer is made of waterproof plywood laminated with 9-15 mm FF with a phenolic coating.

The sides and back of the frame are made of 9 mm FF laminated waterproof plywood with a phenolic coating. The inner frame, vertical railings, connecting pipes and asphalt or concrete mounting plates are made of hot-dip galvanized steel.

Version STEEL PRO

The riding surface is extremely wear-resistant, maintenance-free and weather resistant 6.5 mm textured surface, and its bottom layer is made of waterproof plywood laminated with 9-15 mm HDPE. The sides and back of the frame are made of 9 mm HDPE.

The inner frame, vertical railings, connecting pipes and asphalt or concrete mounting plates are made of hot-dip galvanized steel. The riding surface is 6.5 mm thick.

Pump Track bike parks

These unique bike parks have become the favourite places for active young people of all ages.

The specially designed trail/park consists of sloping curves, jumps of different sizes and embankments that can be used to control speed. A bike park may consist of a single track two meters wide or a collection of different tracks. Track sizes start at 250 m2, but the recommended minimum is 1000 m2.

After receiving information about the potential land plot, we create a concept project and draw up price calculations. We carry out all construction work, from removing and compacting the soil, to landscaping the plot and installing safety signs.

Bike park surface materials

- ASPHALT – a long-lasting vandal-proof solution, designed for various vehicles – bicycles, skateboards, scooters, roller skates, etc.; suitable for year-round use (if there is no snow).

- GRAVEL – a good solution for non-city bike parks that are intended to be used only by cyclists; need maintenance from time to time.

Find out more about the solutions we offer:

Pump Tracks: http://velosolutions.ee/

Pump Track Catalog 2019

Skills Parks: http://thevelomaster.com/